| Barque Glenlee 1896 |

| A photo essay of the rigging restoration of the 3 masted Barque Glenlee. Page 3 |

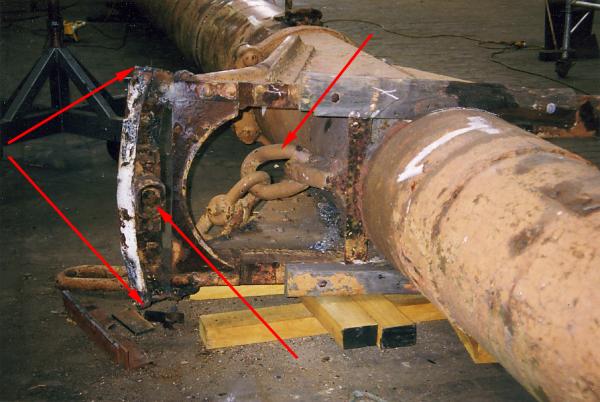

A

B

C

- Cut off main top coping iron

- Main yard sling chain

- Shoe for main lower topsail sling stay ( heavy iron rod that helped

support the weight of the lower topsail yard).

This is the main lower mast. The fore and main mast on the

Glenlee are made up of 3 sections - lower mast, topmast, and

topgallant mast. This photo shows the lower main mast at the

tops. Notice that the tops have been cut away, leaving only a

small span of the original cope iron at "A".

In this view the deck end of the mast is in the background with

the masthead in the foreground. You can also see the heavy sling

chain that help support the weight of the main yard (B).

Determining the arc of the tops was difficult since the tops had

been badly cut up and mangled.

Glenlee are made up of 3 sections - lower mast, topmast, and

topgallant mast. This photo shows the lower main mast at the

tops. Notice that the tops have been cut away, leaving only a

small span of the original cope iron at "A".

In this view the deck end of the mast is in the background with

the masthead in the foreground. You can also see the heavy sling

chain that help support the weight of the main yard (B).

Determining the arc of the tops was difficult since the tops had

been badly cut up and mangled.

Lofted out Top chalklines to begin

fabricating new Tops framework

out of steel.

fabricating new Tops framework

out of steel.

Reattaching and welding the mast sections.

After welding an inner sleeve, the sections

were welded together using 8 welding

passes. All the welds were later inspected

and passed by Lloyd's.

After welding an inner sleeve, the sections

were welded together using 8 welding

passes. All the welds were later inspected

and passed by Lloyd's.

The steel spars (both masts and yards) were reattached to each other by:

- Truing up the original cut to make a clean surface to mate the other piece against

- (Photo A) The pieces were position in slings, dollies, and gantries to enable an accurate weld to be made .

- Sleeving the 2 pieces together with 8 welding passes. All welds were later tested for strength by Lloyd's

and passed.

- (Photo B) Positioning in the dead center of the diameter, a block of wood with a piece of tin that had a

small hole drilled in it. When the 2 spar pieces were brought together, a light shown through at the end,

would signal that the sections where in column when it was visible through the hole at the other end.

- (Photos C & D) After the spar sections were reconnected, they were grit blasted, primed and painted,

ready to be sent aloft .During the grit blasting, one felt like an extra in Sir David Lean's Lawrence of

Arabia.

- (Photo E) Since the spar loft and rigging loft where on different sides of the same space, it was a battle

to keep the grit and dirt off the newly made rigging. One of the methods we used was to wrap all the

service in butcher paper to keep the grit off .

| (A) |

| (B) |

| (C) |

| (D) |

| (E) |

Moving spars outside to make room

for others to be re-assembled. These

are the connected fore and main

topmasts

for others to be re-assembled. These

are the connected fore and main

topmasts

Joining the fore topmast sections. Note

the cut cap iron. New cap irons were

fabricated and weld on.

the cut cap iron. New cap irons were

fabricated and weld on.

| (A) |