| Barque Glenlee 1896 |

| A photo essay of the rigging restoration of the 3 masted Barque Glenlee. Page 4 |

| ~ The Rigging begins ~ |

While the spars were being put back together,

the rigging crew was hires and began training

in the "how" of traditional rigging. The crew

had a variety of experience, but no traditional

rigging experience. One had worked on North

Sea oil rigs and another had done some

theatrical rigging. On the whole everyone

started at the beginning with worming,

parceling, and serving wire rope.

Before we could begin practicing these new

skills a rigging loft had to be created out of the

space. We put down plywood sheeting as

decking and placed welded steel strong backs

and posts to set up the rigging on.

the rigging crew was hires and began training

in the "how" of traditional rigging. The crew

had a variety of experience, but no traditional

rigging experience. One had worked on North

Sea oil rigs and another had done some

theatrical rigging. On the whole everyone

started at the beginning with worming,

parceling, and serving wire rope.

Before we could begin practicing these new

skills a rigging loft had to be created out of the

space. We put down plywood sheeting as

decking and placed welded steel strong backs

and posts to set up the rigging on.

The rigging loft looking towards the river Clyde

The rigging loft looking away from the river Clyde. The large steel

framework is for the overhead hook up needed for splicing wire. The

wire splicing vices mount just below the horizontal overhead steel beam

framework is for the overhead hook up needed for splicing wire. The

wire splicing vices mount just below the horizontal overhead steel beam

One of the welded steel strong back posts.

1 & 1/2 ton come alongs were attached to

the posts to tighten the wire - "put it on the

stretch" They had to be very strong and

were drilled and epoxied bolted to the stone

floor.

1 & 1/2 ton come alongs were attached to

the posts to tighten the wire - "put it on the

stretch" They had to be very strong and

were drilled and epoxied bolted to the stone

floor.

The loft in action. One could smell the

Stockholm tar from a mile away

Stockholm tar from a mile away

The crew learning how to set up the wire

on the stretch safely and the correct way

to "worm, parcel, and serve" using both

serving boards and the larger serving

mallets.

on the stretch safely and the correct way

to "worm, parcel, and serve" using both

serving boards and the larger serving

mallets.

While everyone learned basic marlinespike

seamanship ( knots, bends, hitches) and

how to worm, parcel and serve, only a

couple learned how to splice wire and clap

on wire seizings. There was not enough

time to train everyone.

seamanship ( knots, bends, hitches) and

how to worm, parcel and serve, only a

couple learned how to splice wire and clap

on wire seizings. There was not enough

time to train everyone.

The first piece of wire is cut. This wire

will eventually became one of the 22 wire

foot ropes the ship required.

will eventually became one of the 22 wire

foot ropes the ship required.

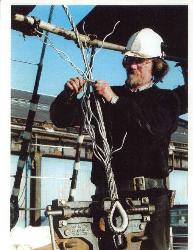

I am splicing up a fore topmast cap

backstay in 1 1/8" diameter wire. One of

the over 275 wire splices needed.

backstay in 1 1/8" diameter wire. One of

the over 275 wire splices needed.

Frank Carr serving a topgallant

backstay. In total over 4,500' feet of

service was done.

backstay. In total over 4,500' feet of

service was done.

Andy Aire and Brian Gray turning in a wire

seizing on a topmast backstay. One of

over 420 wire seizings done on board.

seizing on a topmast backstay. One of

over 420 wire seizings done on board.

Fine example of a wire throat seizing on a

lower shroud turn back. Notice the canvas

chafe protection in the score of the solid

thimble.

lower shroud turn back. Notice the canvas

chafe protection in the score of the solid

thimble.

The Glenlee as she looked on my arrival.

One of the 4 splicing stands

The first splice completed on a fore lower

yard footrope. Only 274 more to go

yard footrope. Only 274 more to go

Leathering the fore upper topsail parral

bucket. Over 13 full hides of leather were

used during the restoration.

bucket. Over 13 full hides of leather were

used during the restoration.

The wire rope for the standing rig was 6x7 galvanized

extra improved plow steel from Spain. Unfortunately it

was coated in a thick wire rope lube/sealer that had to

first be steam cleaned off the wire. I guess my Spanish is

not as good as I thought! Leaving the lube on made

splicing impossible. Also notice some of the bottle

screws on the shelf in the background. Almost 100 were

needed for the rig

extra improved plow steel from Spain. Unfortunately it

was coated in a thick wire rope lube/sealer that had to

first be steam cleaned off the wire. I guess my Spanish is

not as good as I thought! Leaving the lube on made

splicing impossible. Also notice some of the bottle

screws on the shelf in the background. Almost 100 were

needed for the rig