| Barque Glenlee 1896 |

| A photo essay of the rigging restoration of the 3 masted Barque Glenlee. Page 5 |

While the rigging gang was making up all the new wire, the shipwrights and ship

fitters were completing the deck houses and laying a new deck.

fitters were completing the deck houses and laying a new deck.

Additional steel plating was added where it was thin and wasted away. The area at the mast partners is subject to

tremendous loading due to the weight of the tophamper (all the spars and wire) and needs to be very strong. Even

though the ship is not sailing, the wind loading in all of her rigging can generate severe forces and loads on all the

fittings.

tremendous loading due to the weight of the tophamper (all the spars and wire) and needs to be very strong. Even

though the ship is not sailing, the wind loading in all of her rigging can generate severe forces and loads on all the

fittings.

Scaffolding was erected to work on the

bowsprit and headgear when it was finally

rigged.

bowsprit and headgear when it was finally

rigged.

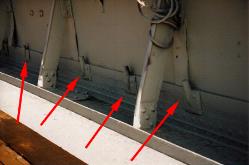

One of the many interesting

challenges of the rig design was

duplicating the angle of the chain

plates. The chain plates have 2

angles - the rake aft and the pitch

inboard. The higher aloft in the rig

the wire ranges the less it is raked

aft and pitched inboard. The chain

plates for the topgallant backstays

are raked less than th topmast

backstay chain plates.

challenges of the rig design was

duplicating the angle of the chain

plates. The chain plates have 2

angles - the rake aft and the pitch

inboard. The higher aloft in the rig

the wire ranges the less it is raked

aft and pitched inboard. The chain

plates for the topgallant backstays

are raked less than th topmast

backstay chain plates.

Example of a

chainplate

chainplate

The original chainplates were cut off by

the Spanish, leaving only a little stub,

barely enough to weld to.

the Spanish, leaving only a little stub,

barely enough to weld to.

Foc's'le head decking with nibbed ends.

The decking is an African hardwood called

Opepe.

The decking is an African hardwood called

Opepe.

Repaired foremast step. The step is a very

strong riveted structure that rests on top of

the keel and is subjected to tremendous

compression loads due to the weight of the

masts, yards, wire, and dynamic loads of

the bottlescrew tension.

strong riveted structure that rests on top of

the keel and is subjected to tremendous

compression loads due to the weight of the

masts, yards, wire, and dynamic loads of

the bottlescrew tension.

Lower hold view during jack hammering

out the old concrete ballast in the frame

bays.

out the old concrete ballast in the frame

bays.

Fitting the new deck houses on deck

Caulking the steel plate lands on the deck house.

Fabricating new deck houses using

traditional riveting techniques. Several old

time riveters from Along the Clyde were

called out of retirement to rivet the houses.

The Song of the Clyde as the staccato of

the riveting hammer was called.

traditional riveting techniques. Several old

time riveters from Along the Clyde were

called out of retirement to rivet the houses.

The Song of the Clyde as the staccato of

the riveting hammer was called.

The new riveted steel deck houses looking from below decks.